Why Should I Care about Moisture?

Edited 14 February 2024

Benefits of Measuring Moisture in Grain Processing

Recent advances in moisture measurement technology are enabling forward-thinking businesses to achieve better control of their grain processing operations, rewarding them with numerous benefits, such as quality improvement, yield maximisation, energy savings and more.

Historically, sensors used in grain have either been expensive and complex to use, fragile and required continual maintenance, or their measurement technology was based on an older technique that was affected by variables other than moisture. This made them less accurate, less reliable, and less repeatable.

Often, this would lead to sensors being switched off completely.

This article highlights some of the benefits of using a modern grain moisture sensor, along with the defining characteristics of the latest sensors, which make them an attractive investment for all producers.

Harvesting and threshing

The efficiency of mechanised harvesting and threshing is mainly a combination of the type of equipment used, the speed of the machinery, and the moisture content of the grain. The integrity of the harvested grain is a key factor in determining the value of the crop, and the machinery is selected depending on the cost, speed, and quality requirements of the producer.

Varying moisture contents must be taken into consideration during harvesting with adjustments made to the table-cutting height, forward speed, and cutter rotational speeds. These adjustments may be made by intelligent machinery or manually.

Research has shown that the percentage of grains broken in maize is significantly affected by the moisture content of the maize and less affected by the speed of the machinery1. Ensuring the moisture is at an appropriate level during harvesting will reduce the time it takes to harvest and enable adjustments to be made to mitigate loss and maintain optimum speed.

Moisture content also has a significant impact during processes such as de-husking. Grains are typically processed through a combination of stages, such as parboiling, steaming and drying. Increased moisture will weaken the bond between the husk and seed, making separation easier, but excessive thermal processing can soften the material, resulting in broken seeds2.

Raised moisture content increases the weight and reduces the amount of grain the machine can carry, requiring more energy to process. If unaccounted for, it will also increase stress and fatigue on the machine, particularly on the threshing and separating mechanisms.

Real-time adjustments for moisture content will reduce wear and extend the life of the machinery and measuring moisture also enables the dry weight yield to be recorded, providing additional historic information about spatial variability in the field.

The presence of mycotoxins in grain is a significant problem that should be addressed by eliminating contaminated products from the food processing chain. Ensuring the correct moisture content, for example, in harvested maize is the most effective strategy to achieve this objective3, as the growth rate of mycotoxins increases with moisture. Knowing the precise moisture level enables the crop to be processed accordingly. Moisture control is particularly important in the first 48 hours after harvesting to prevent initial mycotoxin growth.

Drying and Storage

Once harvested, the crop must be dried and stored.

Mycotoxin contamination in grain can be caused by damaged or cracked material, insect infestation, the drying method used, the time of harvest, and the storage, handling, and processing. The primary factors that drive the growth and development of mycotoxins, once present, are temperature, moisture, and humidity4.

To regulate the storage operations and react to problems in a timely fashion, monitoring and controlling moisture during transfer to storage is essential.

Drying is a common practice to enable the safe storage of grain. Precise control is important to ensure the perfect moisture content is achieved. If the grains are under-dried, the crop is still prone to mycotoxins and spoilage, whereas over-drying is not just an expensive waste of energy but can cause damage and breakage to the grain’s skin, making it susceptible to mycotoxins and insect attacks. Excessive drying can also cause the grains to shrink in size, causing yield loss5.

The material entering the dryer continually varies in water content, making it challenging to regulate the time the material is exposed to the heat and the temperature used: the two primary parameters in the drying process. Inline moisture sensing and control automates the dryer, reducing the risk of contamination or damage, enhancing the quality of the product and saving cost by eliminating wasted energy.

Conditioning

After storage, depending on the material and system requirements, it may be necessary to reintroduce water into the product by conditioning. This process is typically performed before grinding and pelleting operations.

The conditioning process is also used to heat the material to kill bacteria and other contaminants6, to cook ingredients, and to gelatinate starch7. In the same way, moisture control enhances the drying phase, it also improves the conditioning process by monitoring changes in the input material. This allows the control system to react to these changes, ensuring the correct moisture levels in the processed grain.

Grinding

Through mechanical action, grinding reduces the size of food materials such as grains, seeds, fruits, and many more to achieve different chemical and microbiological stability. Grinding, however, is one of the most energy-consuming transformations in many food processes, and one of the primary factors affecting energy consumption during this process, is the moisture content of the grain8.

Toughness is the ability of a material to resist breakage; therefore, tougher material will need more mechanical energy to be reduced in size.

The plasticity or ductility of a material determines the amount of energy absorbed before breaking down and the final size. More plastic or ductile material will need more energy to break, but it will maintain a more regular final shape. In contrast, less plastic or ductile material will shatter into finer and more irregular shards.

A significant factor affecting the elasticity of the grain is the moisture content. By monitoring and controlling the moisture of the material, it is possible to control the elasticity of the material better (and therefore the energy consumption of the process), the final size of the powder particles, and the product quality and yield9.

For these reasons, the moisture content of the grain is often the most important element to regulate before the grinding process.

Transport and flowability

After the grinding process, the moisture remains very important. Moisture content determines the flowability of the particles10, as the bonds between water molecules affect the stickiness and caking effect of the powder. Even small variations in factors, particularly moisture content, can result in caking or bridging that will impair the ability to transport the grain11.

Pelletising

Pelletising is the process of extruding the formulation into cylindrical shapes that are more easily consumed by animals. With a wide range of applications and recipes, the content of the mix varies considerably. The water content, however, remains an important factor and is a key determinant of pellet quality12.

Too dry material is hard to mould properly, can create dust and intensifies the abrasiveness of the material, which increases machine wear. It also raises the operating temperature, affecting performance and increasing wear to the moulds and rollers, as well as requiring more cooling.

An increase in the moisture content of the material leads to softer pellets which may be poorly shaped and stickier. Wetter material increases friction and is more likely to block the pellet mill, and increased moisture running through the machine can also have some degree of corrosive action.

The pellets may also need to be dried to prevent mould formation or other degradation when stored. Measuring moisture at the input of the drier enables feed-forward control of the drying and cooling processes, ensuring optimum performance, minimal energy consumption and improves quality, ensuring optimal pellet integrity and nutritional value.

Control and sensors

In summary, the moisture content in grains affects the cost and the quality of the end products. It is essential to monitor and control the water content of the material at every step of the process to improve efficiency, reduce carbon footprint, and save money, as well as ensure a consistently good product.

Sampling the material is an inadequate approach to controlling moisture content. Samples may not be representative of the full batch, and the delay introduced means the speed of the feedback process cannot adapt to changes in the input material. It is possible, however, to achieve real-time control in the process with inline sensors.

There are several different measurement technologies to choose from several different manufacturers. When choosing a sensor to measure in your process, it is critical that the sensor is cost-effective, simple to install and maintain, and requires minimal maintenance from the manufacturer. This ensures that your engineers have the autonomy to monitor and fine-tune performance without requiring external assistance. Of course, the sensors also need to be accurate, robust, reliable, and repeatable.

Return on investment should be fast, and the overall cost of ownership should be considered over the expected life of the sensor. Additionally, installing sensors from a range of products with identical measurement characteristics has significant benefits, including ease of installation, maintenance and, importantly, calibration. Sensors with identical characteristics may share calibration information and have other benefits.

Some sensors may simply be used without needing an absolute calibration, using a defined sensor reading as a target value rather than defining a moisture percentage which needs to be derived from a calibration routine. If requiring a moisture percentage output, the sensor should be simple to calibrate by on-site staff.

Animal feed recipes are constantly adjusted depending on the availability and price of ingredients. For this reason, it is even more essential for feed producers to use dependable sensors that are not affected by material or ambient temperature or colour or texture of the material.

Installing a sensor that is not repeatable and reliable will add greater uncertainty and one more variable to the process and will require increased attention.

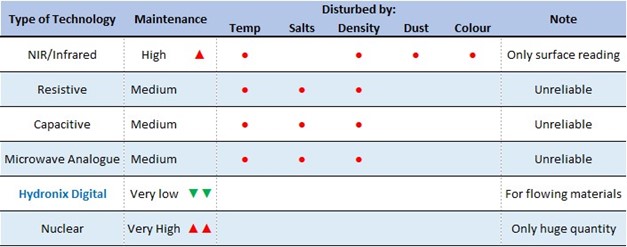

Using a stable technology, it is possible to build up valid data profiles of groups or families of materials and then adjust targets dependent reliably on the formulation being used. Using a sensor from a family of sensors with underlying identical measurement characteristics also enables sensors to be simply removed and replaced or used elsewhere if necessary. There are many moisture sensors available on the market. Six distinct categories are summarised below in Table 1:

Each measurement technique has advantages and disadvantages and should be used appropriately.

The Near Infrared technique (NIR) can give good results but has a high initial cost and requires ongoing maintenance often from external suppliers. As an optical technique, they only measure surface moisture and may be susceptible to dust contamination. NIR systems have the advantage if correctly set up, of being able to measure fat and protein content if this is required.

Resistive, capacitive, and analogue microwave techniques are non-linear and generally lend themselves to more simple applications.

The nuclear technique is very accurate, very expensive and is better used for larger volumes of slow-moving material. It also has safety implications and maintenance requirements.

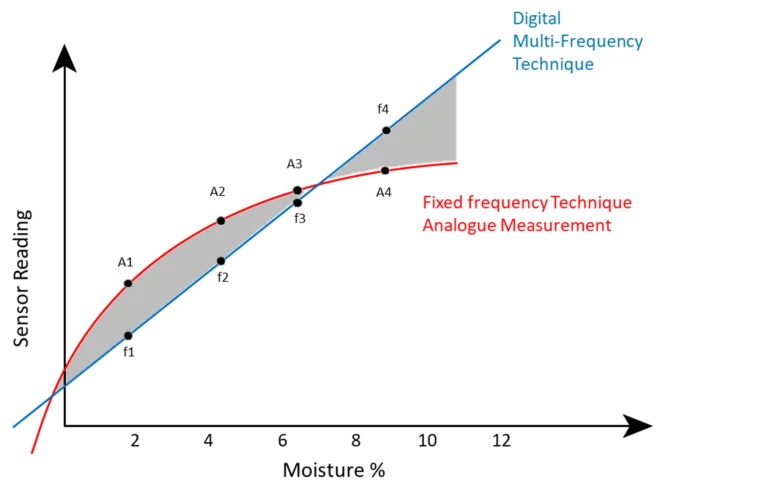

The Hydronix Digital measurement technique uses a unique measurement method designed to respond linearly to changes in moisture across the full working range. This makes them simple to calibrate.

All Hydronix sensors are ‘factory calibrated’ to have identical measurement characteristics and are simple to install. They require practically no ongoing maintenance apart from best-practice quality assurance checks. The sensors measure into the material, which gives a highly representative measurement.

The advantage of a microwave sensor designed to respond linearly to changes in moisture at the point of measurement is shown in Figure 2 below. Sensors that respond in a non-linear fashion must be calibrated within certain moisture ranges, or the measurement must be subsequently linearised using software which incurs accuracy and precision penalties.

Using a sensor specifically designed to measure moisture and does so linearly means that calibration is simplified and accuracy is maximised.

Theoretically, it is possible to achieve a calibration with only two sample points. However, as the calibration process suffers from inherent minor anomalies, Hydronix sensors can also be used in their factory-calibrated, ‘Unscaled’ mode for ultimate precision.

Hydronix sensors are technically more accurate than it is possible to calibrate in the real world, so Hydronix always recommends a diligent approach to calibration. Once calibrated correctly, the sensor will not require recalibration for a given material.

Creating the ideal system

This article has analysed the processing of grains from harvesting to the final product and has identified the importance of water content control and process automation.

From the analysis above, it is possible to define the ideal sensor for optimising the processing of grains:

- Inline sensor capable of multiple measurements per second, to provide quick feedback for the control system to adjust and maintain the target moisture content.

- Robust construction with high-quality materials to withstand harsh industry conditions.

- Linear output that is stable over time, accurate in all conditions and easy to calibrate.

- Storage for multiple calibrations to support multiple recipes.

- Self-contained and easy to integrate into a pre-existing system.

- Low maintenance and cost-effective.

- Full connectivity to allow monitoring from any device and remote analysis.

- High-temperature operating range may also be required.

- Some applications also require ATEX or IECEx certificate.

Thanks to the research and development team at Hydronix, you can find all the above characteristics in the XT series of sensors based on our unique digital microwave technology.

Hydronix, with over 40 years of passion and expertise, provides the best digital microwave moisture sensor technology. We are also driven by the belief that by enabling your success, we help to build a more sustainable future for our children and the generations to come.

Hydronix is represented in over 90 countries around the globe, providing a network of expert engineers in the field who speak your language.

- Xin Feng, Lijun Wang, Shengying Bi, Bo Wang, Zhao Ma and Yunpeng Gao (June 2023). Effects of Threshing Devices, Maize Varieties and Moisture Content of Grains on the Percentage of Maize Grains Broken in Harvesting. Agronomy. ↩︎

- NU Joshi, MN Dabhi and PJ Rathod (2023). A Review on Factors Affecting Dehusking Operation of Different Agricultural Products. The Pharma Innovation Journal. ↩︎

- Lloyd B. Bullerman, Andreia Bianchini. (2014) Good Food-Processing Techniques: Stability of Mycotoxins in Processed Maize-Based Foods. Wiley. ↩︎

- Kumera Neme, Ali Mohammed (2017). Mycotoxin occurrence in grains and the role of postharvest management as a mitigation strategies. A review. Food Control Volume 78, August 2017, Pages 412-425 ↩︎

- Maier, D. E., Bakker-Arkema, F.W. (2022). Grain Drying Systems. https://fyi.extension.wisc.edu/energy/files/2016/09/Grain-drying-Systems-GEAPS-2002-secured.pdf ↩︎

- Yueming Hu, Wei Nie , Xinzhong Hu, Zaigui Li (2016). Microbial decontamination of wheat grain with superheated steam. Food Control Volume 62, April 2016, Pages 264-269 ↩︎

- A. Rahimi, A.A. Naserian, R. Valizadeh, A.M. Tahmasebi, H. Dehghani, K.I. Sung, J. Ghassemi Nejad. (2020). Effect of different corn processing methods on starch gelatinization, granule structure alternation, rumen kinetic dynamics and starch digestion. Animal Feed Science and Technology Volume 268, October 2020, 114572 ↩︎

- Zeyad Arif Ahmed, Rafał Nadulski, Zbigniew Kobus, Kazimierz Zawiślak (2015). The Influence of Grain Moisture Content on Specific Energy During Spring Wheat Grinding. Agriculture and Agricultural Science Procedia Volume 7, 2015, Pages 309-312 ↩︎

- Mohammad Mousaviraad, Mehari Z. Tekeste (2020). Effect of grain moisture content on physical, mechanical, and bulk dynamic behaviour of maize. Biosystems Engineering Volume 195, July 2020, Pages 186-197 ↩︎

- Mohammad Mousaviraad, Mehari Z. Tekeste (2020). Effect of grain moisture content on physical, mechanical, and bulk dynamic behaviour of maize. Biosystems Engineering Volume 195, July 2020, Pages 186-197 ↩︎

- V. Ganesan, K.A. Rosentrater, K. Muthukumarappan (2008). Flowability and handling characteristics of bulk solids and powders – a review with implications for DDGS. Biosystems Engineering Volume 101, Issue 4, December 2008, Pages 425-435 ↩︎

- Keysuke Muramatsu, Andréia Massuquetto, Fabiano Dahlke and Alex Maiorka

(2015). Factors that Affect Pellet Quality: A Review. Journal of Agricultural Science and Technology A 5 (2015) 717-722 ↩︎