Using Moisture Control to reduce the environmental impact of Agri-Food processing

Few people realise that around 30% of the world’s energy is consumed by agri-food systems [1]. Energy is also responsible for a third of agri-food systems’ greenhouse gas emissions. Given this, it’s little wonder that sustainable production is a major concern of the industry.

Clearly, optimizing energy use during agri-food processing can go a long way to making the industry more sustainable, particularly as it faces the impact of rising global energy costs. Many of today’s leading companies are implementing net zero strategies, decarbonising and implementing new methods to reduce waste while trying to protect and even increase profitability.

One of the major consumers of energy in agri-food processes is the heat needed to control moisture in raw materials and semi-processed foodstuffs. Moisture control is vital to maintain the quality and consistency of the product throughout the process, for example drying for storage, milling, pelleting and packaging.

Rice is often parboiled to prevent loss of nutrients during milling and prepare it for consumer cooking requirements. In a typical rice processing plant, the rice grain will be soaked then boiled or steamed at between 90-100°C for a specified time. The rice is then dried, often by recirculating through a drying tower where hot air is blown through it. This drying process takes between eight and ten hours and dries the rice from a moisture content of around 30% to a target of around 12%.

The drying process must be carefully controlled as incorrect moisture levels can lead to problems in subsequent processing stages, such as breakages during milling and colour variation during polishing.

Online measurement offers best accuracy

Unlike spot sampling-based methods, which are both time-consuming and prone to errors, online, real-time moisture measurement allows the control system to automatically react to variations in moisture content. This allows it to adjust the process to continuously achieve a precise moisture level in the material, perfect for storage, further processing, or final packaging.

Obtaining accurate moisture levels is important to prevent under-drying and over-drying. Under-drying can lead to the growth of mycotoxins and can also reduce the storage life of the material. As well as possibly damaging the material, over-drying leads to excessive use of energy, reducing the sustainable credentials of the producer and causing extra costs.

Not only can energy be saved by drying more accurately, the rate at which the material is dried can have a significant impact on the quality of the final material. Many producers are now using variable drying rates throughout the drying cycle to achieve quality improvements as well as cost reduction. Controlling variable drying rates can only be achieved using in-line, real-time moisture measurement.

The moisture level of the product needs to be reduced to a maximum allowed value – getting as close as possible to this value reduces unnecessary drying. This requires a moisture sensor that is as precise as possible. Even an increase in precision of 0.5% can mean a significant saving in energy use.

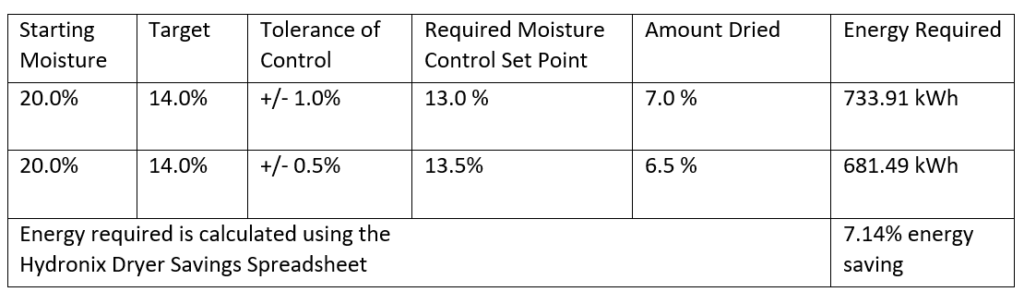

If a material needs to have its moisture level reduced from 20% to a target level of 14%. With a moisture sensor with a precision of +/- 1.0%, the moisture set point needs to be 13.0% to be sure of hitting a figure on or below the target. The amount of moisture removed will therefore be 7.0% which requires over 733 kWh (146.6 kgCO2e) of energy [2].

Employing a sensor with a precision of +/- 0.5%, the set point can be defined as 13.5%. Because this is closer to the maximum target value, moisture only needs to be reduced by 6.5%, only needing 681 kWh (136 kgCO2e) [2]. This gives a saving of 7.14% in energy use.

Using the appropriate drying rate for the moisture in the product is another benefit of dryer control. Drying at too high a temperature can damage the product. By using a moisture control system in its production, one Hydronix customer reported a reduction in broken grains of 2.5%, increasing its yield of premium quality product by 4,000 kg per week.

Choosing a moisture sensor

The ideal sensor would be highly precise, would automatically compensate for changes in operating temperatures and be robust enough to withstand wear.

A sensor based on a digital measurement technique has a linear relationship between measured moisture percentage and the sensor reading, a sensor based on an analogue technique is inherently non-linear. A linear relationship simplifies calibration and ensures the best accuracy across the entire working range as opposed to non-linear techniques. These have a complex relationship with the moisture as the material gets wetter and are more difficult to calibrate.

The Hydronix XT, EX and FS range of sensors have been specifically designed for use in the agri-food industry. These sensors have been designed to suit food safe applications, explosive atmospheres, and high temperatures while maintaining a precise, temperature compensated measurement across the moisture range of the material.

With precise measurement of moisture content, agri-food companies can ensure they use energy more efficiently, building a business that contributes to a more sustainable world.

References:

[1] Renewable energy for agri-food systems: International Renewable energy Agency and the Food and Agriculture Organization of the United Nations, 2021

[2] Hydronix dryer energy saving spreadsheet, 2022. Contact enquiries@hydronix.com for more information