7 things to consider when improving moisture control in food production

In the manufacture of foodstuffs, achieving the right moisture content is paramount. Too little moisture in the ingredients and the product might go stale too quickly or have an incorrect consistency. Too much moisture content and certain foods could develop moulds.

Texture, weight, colour, taste, and shelf life – can all be affected by incorrect moisture content, with the risk of costly product recalls and lost production time.

Getting ingredients to the correct moisture content often involves drying them, so moisture measurement is vital if manufacturers are to avoid using excess energy.

So, what do we need to consider in moisture measurement in food production – and what moisture sensors will be suitable in this demanding application?

1. When and where do I measure moisture?

Moisture measurement of foodstuffs is carried out at various stages depending on the processes used. For example, ensuring the moisture content of coffee is controlled precisely will give a more consistent product quality and reduce wasted materials.

The next stage is spray drying in an evaporator, where the remaining moisture is evaporated to leave a fine powder. Measuring moisture at this stage can enable real-time control of the drier to optimise energy use.

2. What are the main moisture measurement methods?

Several moisture measurement methods exist. For example, it is possible to measure the temperature of the exhaust gas leaving a dryer to give an approximation of the moisture content of the foodstuff being dried. This approach does not directly measure the water present, making it unreliable.

Another method is infrared. The drawback here is that this is a reflective technique, which can only give a surface measurement.

The most accurate method is to determine the moisture throughout the product. This can be done using a microwave moisture sensor, where the effect of moisture on a microwave resonator can be measured and calibrated to changes in the amount of moisture in a material. Microwaves penetrate deep into the material being measured and so will be affected by changes both on the surface and beneath it. This gives precise measurements of the moisture present, data which can be sent to the plant control system to allow automatic adjustments to production machinery.

Hydronix moisture sensors are all based on this highly accurate microwave technique.

3. Is the sensor food safety compliant?

Materials that come into contact with foodstuffs are known as Food Contact Materials or FCMs. The European Union Regulation (EC) 1935/2004 regulates FCMs – specifically, article 3 states that FCMs may not release constituents into food at levels that could endanger human health or bring about changes in the composition, smell, or taste of the food.

Hydronix has launched a new moisture sensor, the Hydro-Mix XT-FS, that fully complies with the regulation.

4. Does the sensor offer the right materials and IP level for use in a food environment?

Vessels used in food production need to be able to resist frequent washdowns between batches and the same is true of any sensors used. The vessels and the sensor housings both need to be made of stainless steel to allow washdown.

The sensors may also need to operate in dusty environments so will also need to be proof against dust ingress.

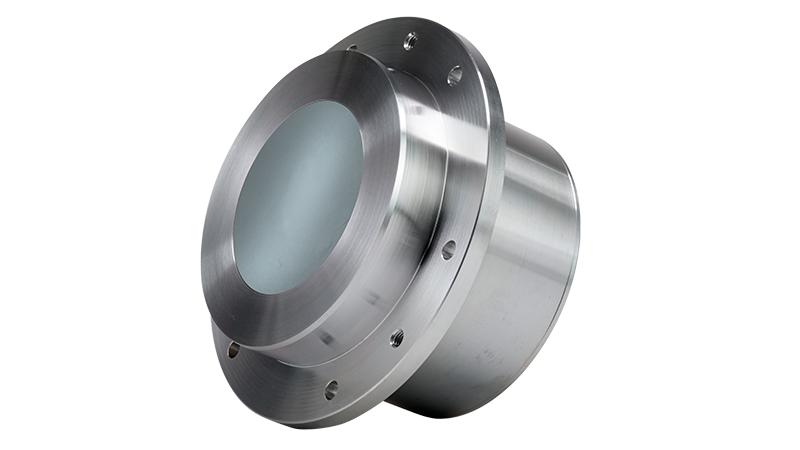

The Hydronix Hydro-Mix XT-FS has a body made of a highly corrosion-resistant stainless steel and is fully protected against water and dust ingress to IP69.

5. Will it stay accurate?

Moisture sensors need to offer reliable performance to ensure ingredients are maintaining high quality at all stages of the process. Unlike infrared techniques, Hydronix digital microwave sensors require little or no regular maintenance. The Hydronix Hydro-Mix XT-FS is easy to calibrate, with no need to recalibrate while using the same material.

Accuracy is also maintained through advanced digital signal processing, which provides a clear signal with rapid response. The sensor also offers full temperature compensated measurement to ensure accuracy as temperatures in the processes change.

6. Where can I install the sensor?

Many items of equipment in a food plant need to have moisture measurement sensors – these can include hoppers, vats, ducting, mixer systems, dryers and conveyors. This makes it essential for the sensor to have convenient mounting options to ensure it can be mounted where needed.

This need is met by the Hydronix Hydro-Mix XT-FS. The unit comes complete with a fixing plate that can be attached to the vessel wall.

The sensor body has a flange mounting to attach it to the fixing plate and seals with an O-ring, allowing installation in dusty or liquid processes or applications.

7. How can I access data and monitor process performance?

Getting easy access to the sensor data and analysing it is vital to ensure processes are performing as expected.

This is well catered for by the Hydronix Hydro-Mix XT-FS. The unit offers two analogue outputs, digital RS485 communications and configurable digital inputs/output, as well as alarms.

It can also communicate remotely with Hydronix’ Hydro-Com software, allowing all sensor parameters to be easily configured.

Connecting sensors to the Hydro-View or Hydro-Hub enables users of Ethernet/IP. PROFINET and PROFIBUS networks straightforward access to live sensor data.

Ideal for food production

Moisture sensors are a useful device in many industries, but in food and beverage, they are essential. When it comes to consumer safety and meeting the regulations that safeguard it, there is no alternative to using a high quality, food safe moisture measuring device.

The Hydronix Hydro-Mix XT-FS meets these demands. Based on the highly accurate microwave method used by all Hydronix’ moisture sensors and using a food safe ceramic faceplate, the Hydronix Hydro-Mix XT-FS is the ideal solution for moisture measurement in a food processing environment.