Moisture Measurement in Asphalt Production

When a panel of industry quality control experts was asked what automated measurements would add value to asphalt production, “moisture content on belts / in bins” and “automatic gradation and moisture measurement from belt sampling” came in the top 3. Do these sound like familiar measurements that would add value to your asphalt production?

The increasing cost of raw materials and energy has made asphalt producers look into their production process in much greater detail than in the past. Proven in-line technologies are now available that can provide a real economic benefit and allow greater process control reducing costly on-site testing and off-line forms of control. The need for more exact process control is further reinforced by moving towards more plant/process certification. Instrumentation has become a major part in allowing asphalt producers to differentiate themselves from others through repeatable quality, reliability and efficiency.

This differentiation and ‘getting it right first time’ can be the difference between winning a job and losing an important customer.

Increased quality control and assurance has also been reflected by developments in national standards have also reflected increased quality control and assurance. In France, asphalt standards have been updated to require producers to measure moisture continuously for the production of Level 2 asphalt (NF P 98 728). In the USA, NCAT (National Centre for Asphalt Technology) carried out an investigation into improving HMA (Hot Mix Asphalt) production technologies. In their conclusions, they recommended the online belt sampling of materials and moisture content compensation.

Sources of Variation in Moisture and Their Effects

When a panel of industry quality control experts was asked what automated measurements would add value to asphalt production, “moisture content on belts / in bins” and “automatic gradation and moisture measurement from belt sampling” came in the top 3. Do these sound like familiar measurements that would add value to your asphalt production?

The increasing cost of raw materials and energy has made asphalt producers look into their production process in much greater detail than in the past. Proven in-line technologies are now available that can provide a real economic benefit and allow greater process control reducing costly on-site testing and off-line forms of control. The need for more exact process control is further reinforced by moving towards more plant/process certification. Instrumentation has become a major part in allowing asphalt producers to differentiate themselves from others through repeatable quality, reliability and efficiency.

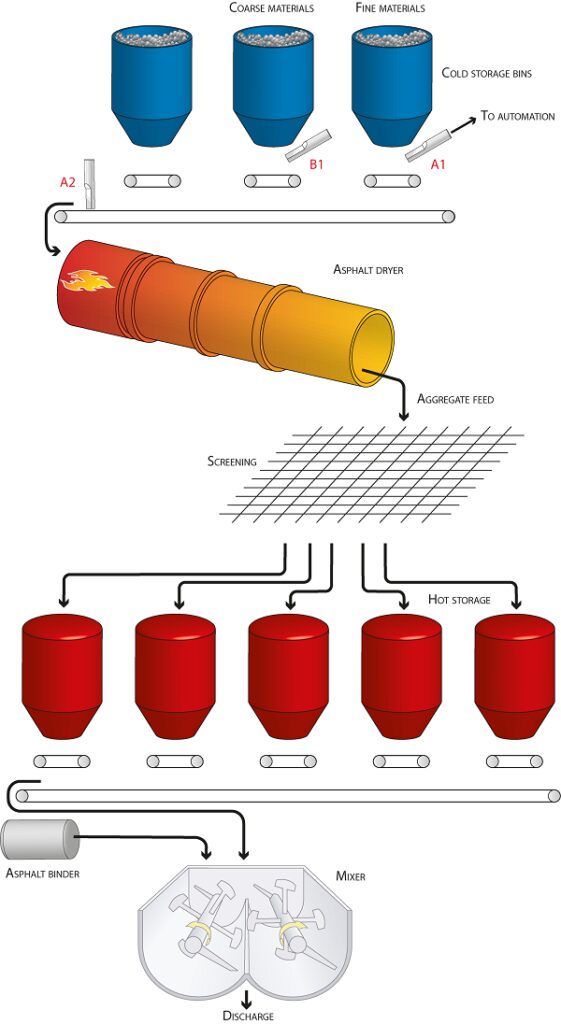

Batch Plant Operations

Precise control may be achieved with a sensor measuring in the fine material which is the most susceptible to moisture variation (A1 below). Although not often required, more precise control may be achieved by measuring in the coarse materials (B1).

The most popular and simple method is to install a single sensor (at position “A2”) measuring in the blended material. This is used to manually or automatically adjust the feed rate of the fine material to ensure that the hot bins are filled evenly. Other benefits include:

- Inconsistent feeding of aggregates from the cold bin can lead to some hot bins overfilling while others remain low on materials.

- Moisture variations can lead the dryer to work inefficiently, over-drying already dry aggregate or outputting insufficiently dry material.

- Moisture variations can lead to aggregates leaving the dryer and entering the hot storage bins at different temperatures. This can lead to variations in the hot storage bins that require correcting.

- Adjust the dryer rate taking into account the moisture content of the aggregates being fed, resulting in energy savings.

Without moisture measurement:

- Unknown aggregate dry weights

- Dryer rate is adjusted by the exhaust temperature in a retroactive manner

- Occasional overflow and/or insufficient material in hot storage bins due to variations in the wet aggregate fed to the dryer

Without moisture measurement:

- Unknown aggregate dry weights

- Dryer rate is adjusted by the exhaust temperature in a retroactive manner

- Occasional overflow and/or insufficient material in hot storage bins due to variations in the wet aggregate fed to the dryer

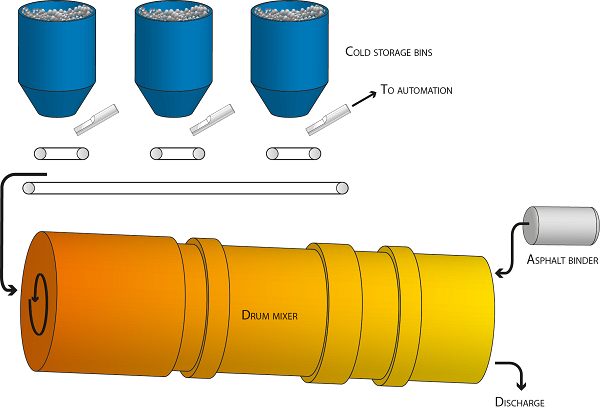

Continuous (Drum) Plant Operation

In the production of asphalt by drum mixing, aggregate gradation is controlled at the cold feed and therefore ensuring the cold feed’s accuracy is essential. Installing Hydronix Hydro-Probe moisture sensors at the belt weighers or at the base of the cold feed bins allows real-time feed adjustment ensuring that the correct dry weight of aggregates is loaded into the drum mixer, resulting in:

- Increased yield and reduced asphalt binder usage through correct aggregate gradation

- The burner rate can be adjusted to suit the moisture content of incoming materials, allowing efficient monitoring

- Energy savings (see Return on Investment below)

- Control of final HMA moisture content

- Reduction in inadequate adhesion between asphalt binder and aggregates

Without moisture measurement:

- Unknown dry weight in aggregates results in incorrect asphalt grading

- Possible over-drying of aggregates

- Occasionally incorrectly graded asphalt

With moisture measurement:

- Real-time “dry weight” grading

- Reduced asphalt binder usage

- Burn rates adjusted in real-time avoiding over-drying

- Well-graded asphalt with correct HMA moisture content and density

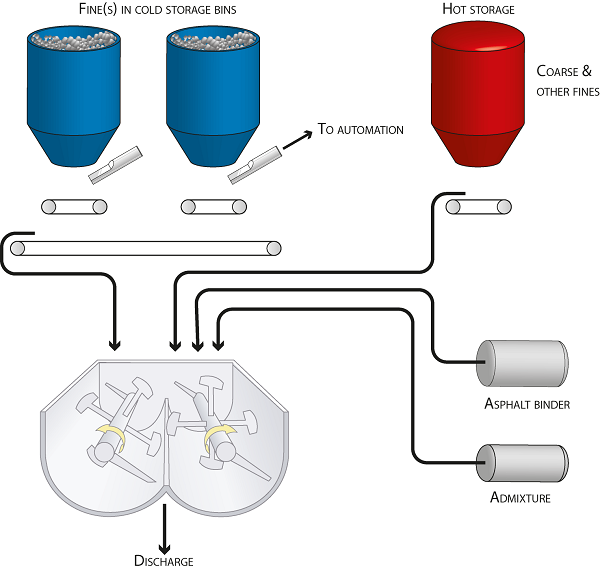

Warm Asphalt Operations – Low Energy Asphalt and Foamed Asphalts

Warm asphalt production techniques require a higher degree of accuracy in aggregate gradation to ensure asphalt quality comparable with other HMA’s. The role of water is essential to achieve the desired “foaming” effect when mixed with the bitumen, allowing the system to uniformly coat all the aggregates.

Hydronix equipment allows real-time and online moisture measurement of the aggregates before they are fed into the pugmill, mixer or drum. With a feed-forward automation system, producers can correct aggregate weights in real-time. For techniques that use the water in the aggregates themselves for the foaming effect, information about the quantity of water being fed into the mixer or pugmill can also be known.

Without moisture measurement:

- Unknown dry fine aggregate weight loaded into the mixer

- Unknown water in fines added into the mixer

- Potential for incorrect foaming effect

- Fine aggregate gradation variation

Without moisture measurement:

- Unknown dry fine aggregate weight loaded into the mixer

- Unknown water in fines added into the mixer

- Potential for incorrect foaming effect

- Fine aggregate gradation variation

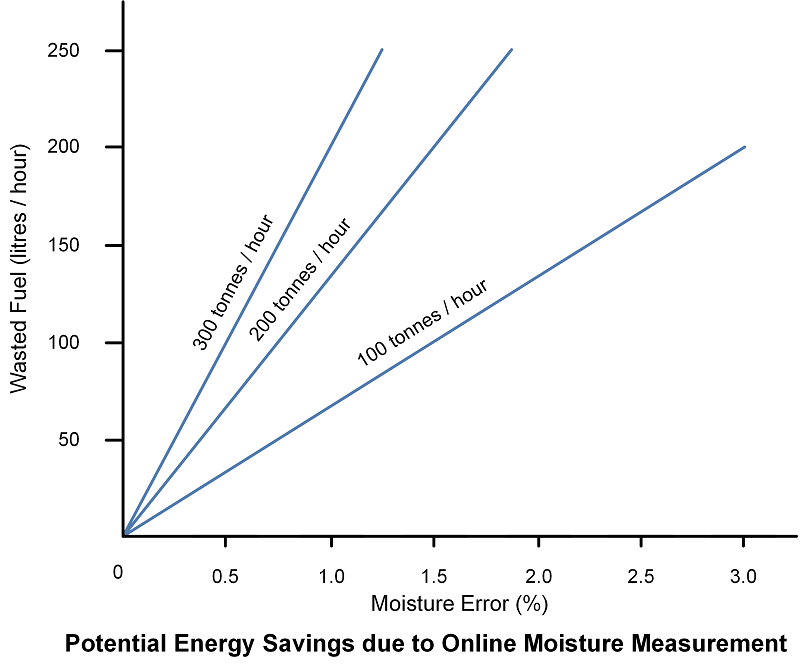

Return on Investment

It has been found that an increase in 1% moisture in a tonne of aggregate can result in an additional 0.6 litres of fuel being consumed to evaporate it. At 6% moisture, 4 litres of fuel are required to dry 1 tonne of aggregate. Once dry, 3 litres of fuel are required to heat the

aggregate to 150 degrees centigrade meaning that more energy is used in drying the aggregate than in heating it.

In practice, the dryer or drum’s exhaust temperatures are already measured and used for feeding back information into the burner control. However, online moisture measurement allows real-time dryer/drum adjustments relating to the material inside, not the material already discharged. This reduces the process control time lag and ensures that the correct dry weights are being loaded into the dryer resulting in savings and quality improvement

If a plant runs 300 tonnes of asphalt per hour at 6% moisture, it will be using 1,200 litres per hour of fuel to dry the aggregate before it is heated up to the correct temperature. If the moisture content then changed from 6% to 5% without the dryers being adjusted for one hour, that would equate to 180 litres of fuel being wasted in that one hour. Were this to be the case, Hydronix moisture measurement equipment would pay for itself in approximately 30 production hours. A reduced process control time lag continuously improves the efficiency of the plant. In most cases, Hydronix moisture measurement systems will pay back within the first 3 to 6 months in operation.

Moisture measurement can also be used to evaluate the dryer’s performance. Should the exhaust temperatures and incoming moistures not match (exhaust temperature increases with reducing moisture contents or vice-versa) there may be a requirement to tune the dryer.

There are other economic effects to moisture measurement. By knowing the correct moisture content in the aggregates, it is possible to maximise the efficiency of the drying process to reduce over-drying and wasted production time, therefore increasing the yield of the plant. Customers using automated moisture measurement consistently report improved output rates.

Installation and Commissioning of a Moisture Sensor

The wide range of digital moisture measurement sensors supplied by Hydronix can be used for installations in the base of the cold feed bins, on the feed belts, or alternatively on a loading “plate” as used by CETE (Centre D’Études Techniques de l’Équipement) in testing.

It has been found in practice that the first two positions are generally the easiest installation locations.

Calibration consists of finding the linear correlation between the sensor’s “unscaled” reading (always 0 in air and 100 in water, allowing easy sensor swap-out if required) and the moisture content in a particular aggregate. This is done by simply running material past the sensor’s face and taking a reading of the sensor’s unscaled value. A sample of the material is taken and then oven-dried to find its moisture content as per the applicable standard. Once the above procedure has been carried out for a few points over the moisture range of the aggregate, the sensor will accurately read moisture – online and in real-time.

It Pays to Invest in Moisture Control

Moisture is clearly not the only issue the asphalt producer has to contend with to ensure he meets quality control requirements within tight economic constraints. However, it is a simple improvement that brings immediate, quantifiable returns. Accurate moisture measurement and control is now well established and proven to directly reduce costs as well as ensure a consistent quality product improving competitiveness.