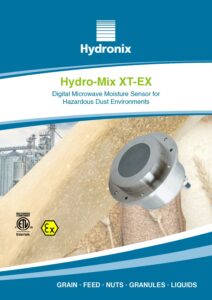

Measurement:

- Moisture

- Ambient temperature

Typical Materials:

- Animal feed

- Grain

- Biomass

- Organic material

- Agricultural material

Unique Key Features:

- Sensor certified for use in ATEX, IECEx and NEC/CSA Explosive Atmosphere (Dust), suitable for Zone 20 process environments, Zone 21 external to process.

- Choice of measurement modes for optimum sensor performance.

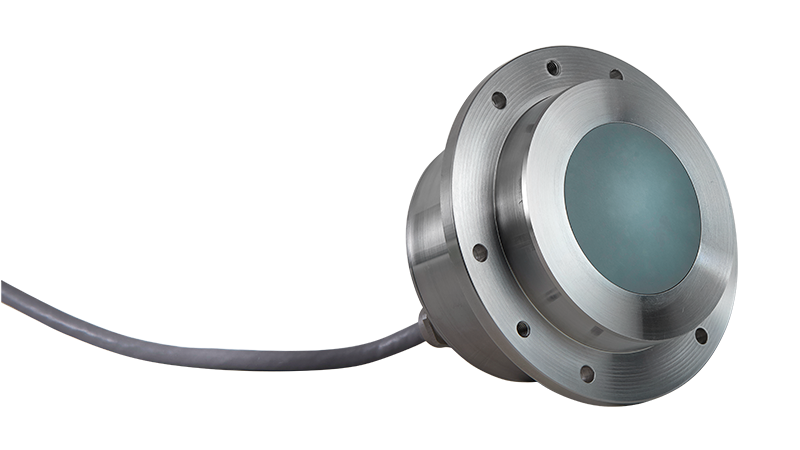

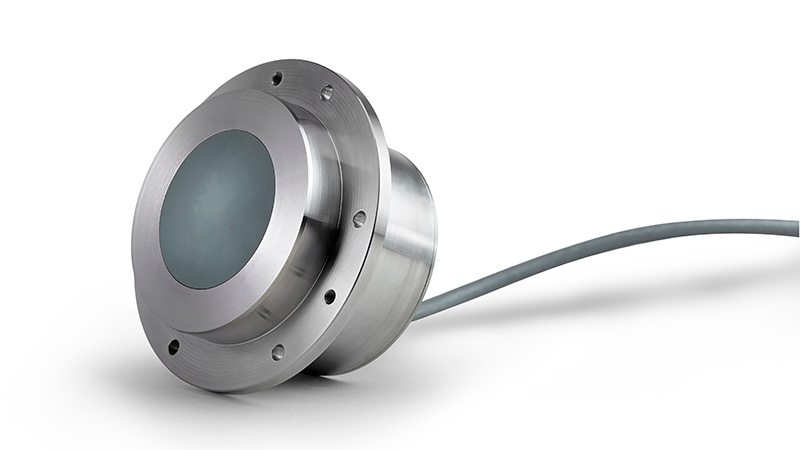

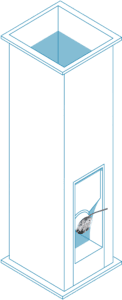

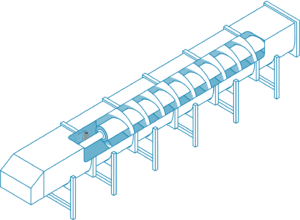

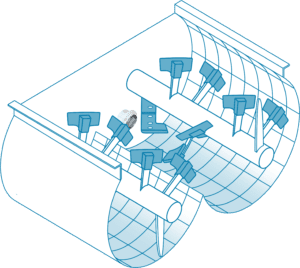

- Fitted flush in the floor of mixers, ducting or conveyors.

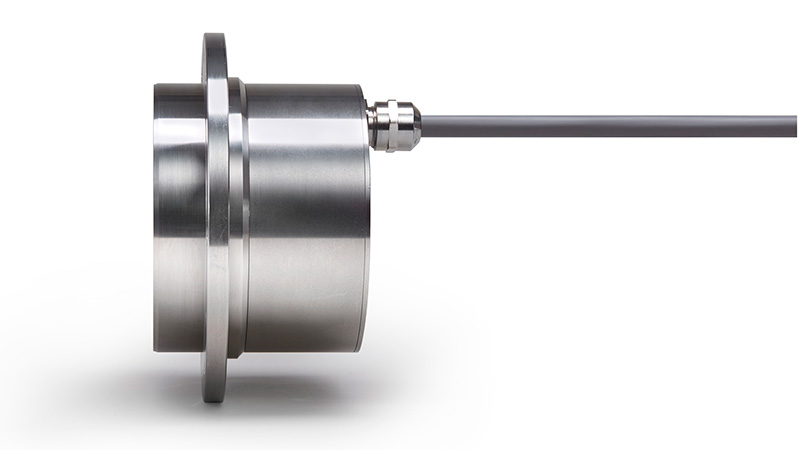

- 5010 HMXT Fixing Plate Kit (Fixing Plate, Bolts and O-Ring), required

- 5015 HMXT Fixing Plate

- 5020 HMXT O-Ring

- 5025 HMXT Fixing Plate Bolts

- 5030 HMXT Blanking Plug – used to create a seal if HMXT is removed

- Digital Technology

- Digital technology provides precise, linear moisture measurement.

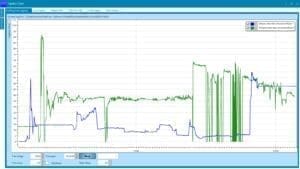

- Advanced Digital Signal Processing

- The sensor response may be adjusted remotely using the Hydro-Com software to minimise the effects of noise of the measured signal. Advanced Digital Signal Processing provides a clear signal with a rapid response.

- Measurement Modes

- Choice of measurement modes for optimising sensor performance in a variety of applications and material types (except Hydro-Probe).

- Fully Temperature Compensated Measurement

- The sensor internally adjusts for mechanical changes due to temperature fluctuations

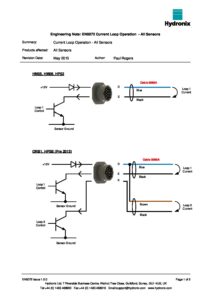

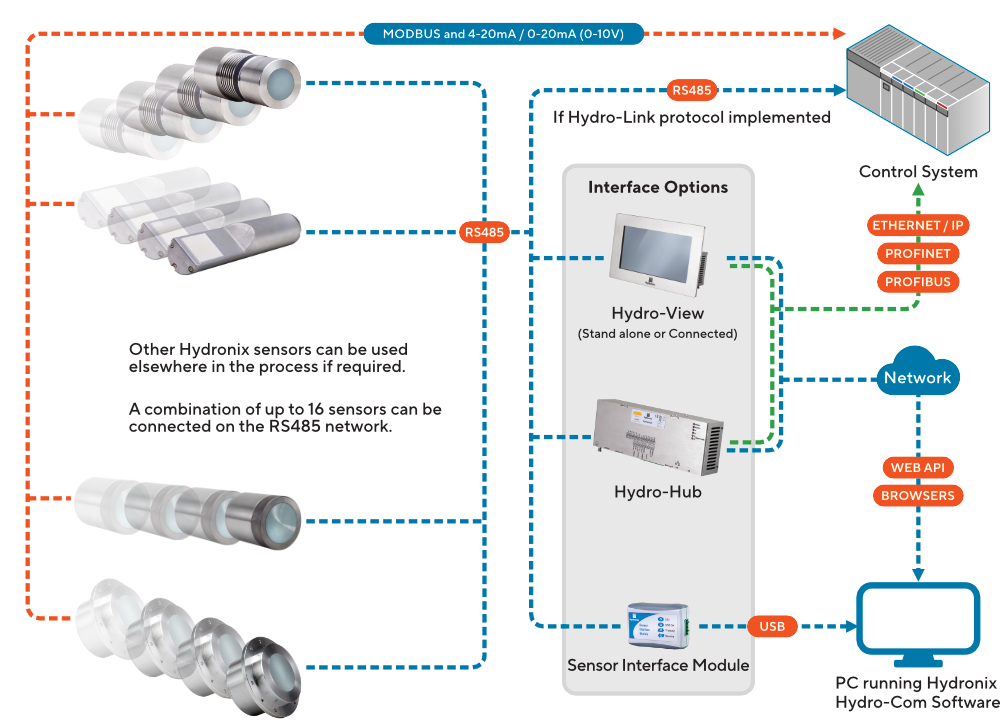

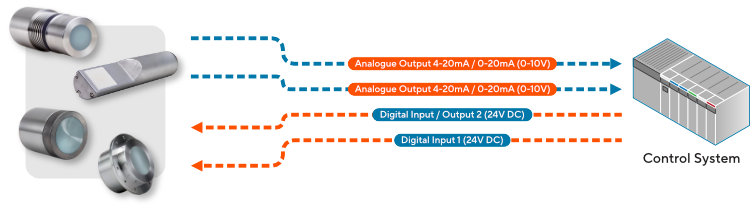

- Easy to Interface

- Two analogue outputs and digital RS485 communications and configurable digital inputs / output make the sensor simple to integrate into a control system. Includes Modbus.

- Fast Measurement

- Measuring at 25 times per second, the sensor continuously detects changes in the moisture of the materials throughout processing.

- Temperature Measurement

- Temperature output is available to provide a readout of material temperature.

- Accuracy of Measurement

- All measurements can be calibrated to an accuracy of 0.2% for aggregates (0.1% in the mixer) and 0.5% for other materials.

- Sensor Configuration

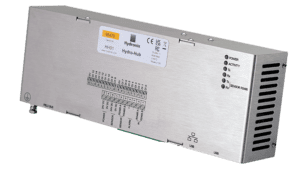

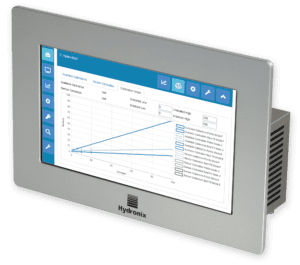

- Sensors can be remotely configured using Hydro-Com diagnostic software or Hydro-View/Hydro-Hub. All readings and sensor parameters are available including the type of output and filtering characteristics.

- Calibration

- The sensor may be internally calibrated using Hydro-Com software, or the linear output may be calibrated within the control system or remotely by using the Hydronix Hydro-View/Hydro-Hub interfaces.

- Simple Power Requirements

- The sensor may be powered from a 15-30V dc supply. Multiple sensors may be driven from a single power source.

Modbus to control system

Input / Output connections

Recommended field cabling:

- Six pairs twisted (12 cores total) screened (shielded) cable with 22 AWG, 0.35mm2 conductors

- Screen (shield): Braid with 65% minimum coverage plus aluminium/polyester foil

- Recommended cable types: Belden 8306, Alpha 6373

- Maximum cable run: 100m, separate to any heavy equipment power cables