Sugar Production – Brix and Solids Sensors

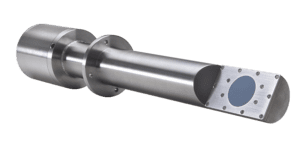

It is critical to measure the dissolved solids or Brix content online during the crystallisation and evaporation processes to monitor the process and control the introduction of the seed crystals. Hydronix sensors can be installed in many locations, including Batch and Continuous Vacuum Pans, and are used to monitor this in real-time, ensuring improved process efficiency and product quality.

Sensors can also be used when processing sugar process byproducts during the production of animal feed to measure the moisture content online in conveyors, ducts/chutes, mixers, hoppers and silo outlets. They are typically used to enable products to be dried efficiently, avoiding over-drying, increasing yield, and decreasing dryer energy costs.

Online measurement before conditioning and pelletising also ensures quality, and a final quality check before storage avoids products with insufficient shelf life.

Typical Applications

Typical Materials

- Sugar

- Syrup

- Molasses

- Beet shreds

- Bagasse

- Animal feed

Process Control

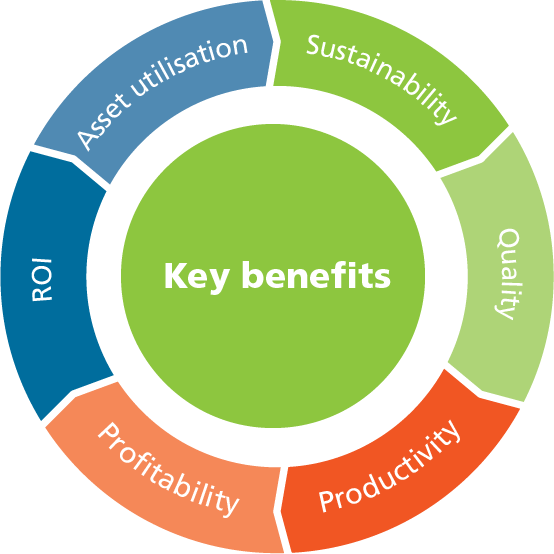

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Controlling Moisture in Dried Sugar Beet Pulp

The increasing cost of inputs such as raw materials, energy and labour are forcing sugar beet processors to look more closely at controlling their overall cost of production. A simple…

Read more