Food Production

The main benefit of moisture measurement in the food and beverage industry is that the final product will be consistent, and the process controlled efficiently.

Monitoring the moisture helps by decreasing spoilt or wasted products, lowering energy costs by controlling dryers efficiently, and finally, reducing process downtime.

Typical Applications

Typical Materials

- Coffee

- Cacao

- Flour

- Wheat

- Barley

- Rice

- Other foodstuffs

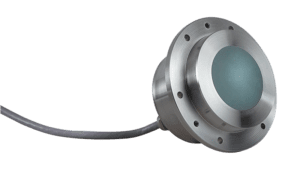

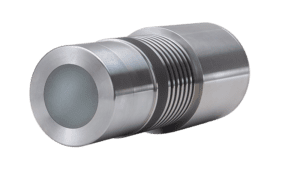

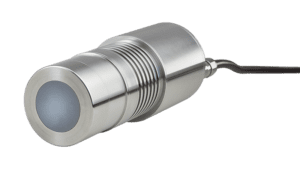

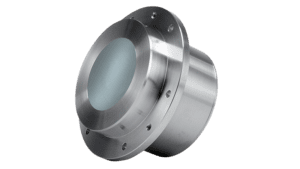

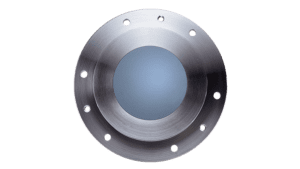

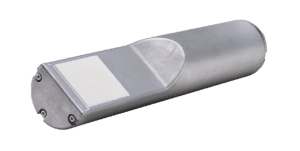

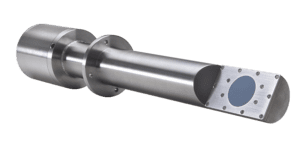

Related Products

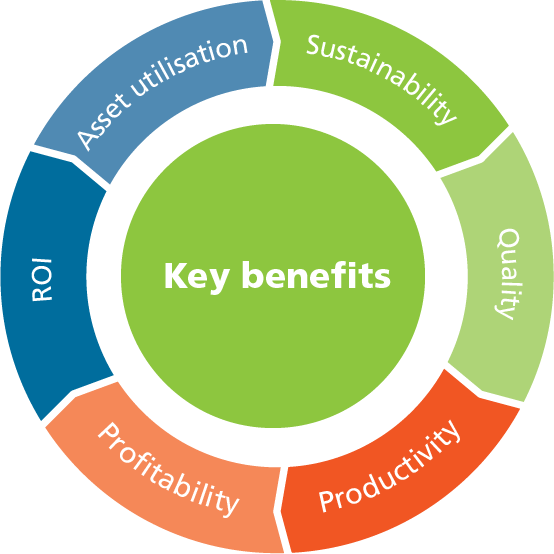

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

7 things to consider when improving moisture control in food production

In the manufacture of foodstuffs, achieving the right moisture content is paramount. Too little moisture in the ingredients and the product might go stale too quickly or have an incorrect…

Read more

Coffee – Finding the perfect moisture from bean to cup

Getting the perfect cup of coffee has many steps before you can enjoy that rich aroma and taste, and controlling moisture is essential to ensure the highest quality. We…

Read more

Controlling Moisture to Minimise Food Waste

Food is a vital and valuable commodity, yet according to Earth.Org1 around one-third of the world’s food, amounting to 1.3 billion tons, is either lost or wasted. The benefits of…

Read more

Using Moisture Control to reduce the environmental impact of Agri-Food processing

Few people realise that around 30% of the world’s energy is consumed by agri-food systems [1]. Energy is also responsible for a third of agri-food systems’ greenhouse gas emissions. Given…

Read more