Pet Food

When manufacturing pet food: dry, semi-moist or moist, it is vital to ensure that the final product is consistent, the process is repeatable, and the food still retains all of its nutritional value. By adding moisture control at various steps in the process such as drying, mixing and pelletising/extrusion, the manufacturer can ensure that the food and kibble are optimal for pets whilst improving the efficiency of the plant and reducing waste and energy.

Typical Applications

Typical Materials

- Fish meal

- Shrimp meal

- Wheat

- Corn

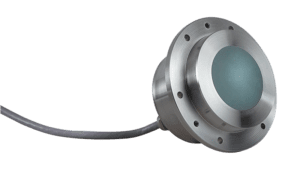

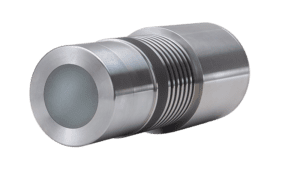

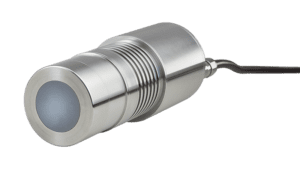

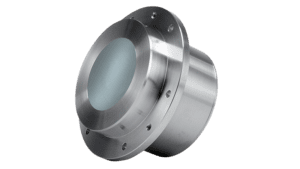

Related Products

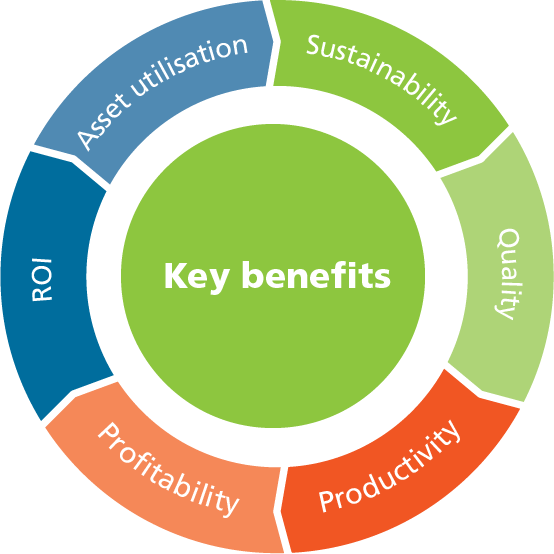

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Moisture Measurement Benefit in Feed and Grain

Feed and grain producers will be familiar with the benefits of being able to control moisture during the various stages of the production process. Monitoring the moisture in the raw…

Read more