Coffee – Finding the perfect moisture from bean to cup

Getting the perfect cup of coffee has many steps before you can enjoy that rich aroma and taste, and controlling moisture is essential to ensure the highest quality. We look at water control throughout the coffee production process and how the latest microwave measurement technology from Hydronix ensures accurate moisture readings.

With its focus on bringing every coffee drinker the perfect cup, the coffee bean processing industry must ensure quality at every stage. One of the critical parameters that needs to be measured and controlled at many of these stages is the coffee beans’ moisture content.

Accurate, repeatable inline moisture measurement is essential to the coffee bean processing industry and the latest Digital Microwave Technology makes this possible, ensuring a plant-wide solution that can guarantee final product quality.

Controlling moisture can bring benefits at many stages of the process, but until now, the high purchase costs and the extensive maintenance required by existing solutions has restricted where this technique can be used.

Hydronix employs their unique measurement technology, which has been developed and proven over many years in other industries, to dramatically lower the cost of moisture measurement.

This enables multiple sensors to be installed throughout the coffee production plant, giving much greater visibility and control of the whole process.

The journey of a coffee bean

Coffee’s journey to the consumer starts with the harvested red coffee berries. These are washed, and the green coffee beans are then extracted and dried. They are then milled to remove the outer shell.

A second drying stage then ensures the beans reach the correct moisture target, preventing them from spoiling.

Different varieties of green beans are then blended to produce different flavours and intensities before proceeding to the crucial roasting stage. By turning fats inside the beans to oils and caramelising the sugars, this process is responsible for the distinctive aroma of the coffee.

Following roasting, the beans are cooled and then cooled in air.

It’s important to know the exact moisture before and after the roasting process to ensure a repeatable result.

The next stage sees the roasted beans going through a mill, grinding them ready for packaging and sale.

Again, the water content is a key element as the moisture of the roasted beans is a major factor in determining the final shape and size of the ground coffee particles – beans with lower water content will break down into finer, irregular pieces, while wetter beans produce more rounded, more regular particles.

A final check on the moisture content of the ground coffee helps to ensure it is of the correct quality and has the required shelf life before being sent to the packaging stage.

Finally, the coffee is ready to brew just the way we like it.

Controlling moisture from bean to pack

Many stages of the process, from the green beans to final packaging of the finished product, demand moisture control to improve the yield and quality of the coffee.

Laboratory tests are standard procedures used in the process. In these, the moisture content of a collected sample is determined by heating it until all the water has evaporated and only the dry material remains. The difference in the weight of the sample before and after heating allows the moisture content to be calculated.

One drawback of this method is the extensive time required, making it impossible to provide valuable real-time feedback to control the process. Also, as only small quantities of the large volumes of product flow are tested, this type of test is often not representative because of the sampling errors it introduces.

Online moisture sensors allow continuous, rapid measurements of the material flow, and several different types are available. However, the high degree of accuracy and stability required during the coffee production process means that not all measurement techniques are suitable.

There are some sensor technologies, one example being Near Infra-Red, that give very good accuracies and can give a lot of extra information about the material itself, such as protein and fat content, but these methods have the disadvantage of being expensive, with high, continuing maintenance costs. They are also affected by dust and suffer from a low component life.

There are other, cheaper sensor technologies but the techniques used suffer from interference caused by impurities in the material flow, such as salts, as well as environmental factors, such as temperature, which means a much lower precision for the final measurement.

Techniques based on microwave moisture measurement techniques are recognised as giving a very high degree of precision and accuracy. Yet, one often overlooked factor in microwave technology is the linearity and stability of the measurement.

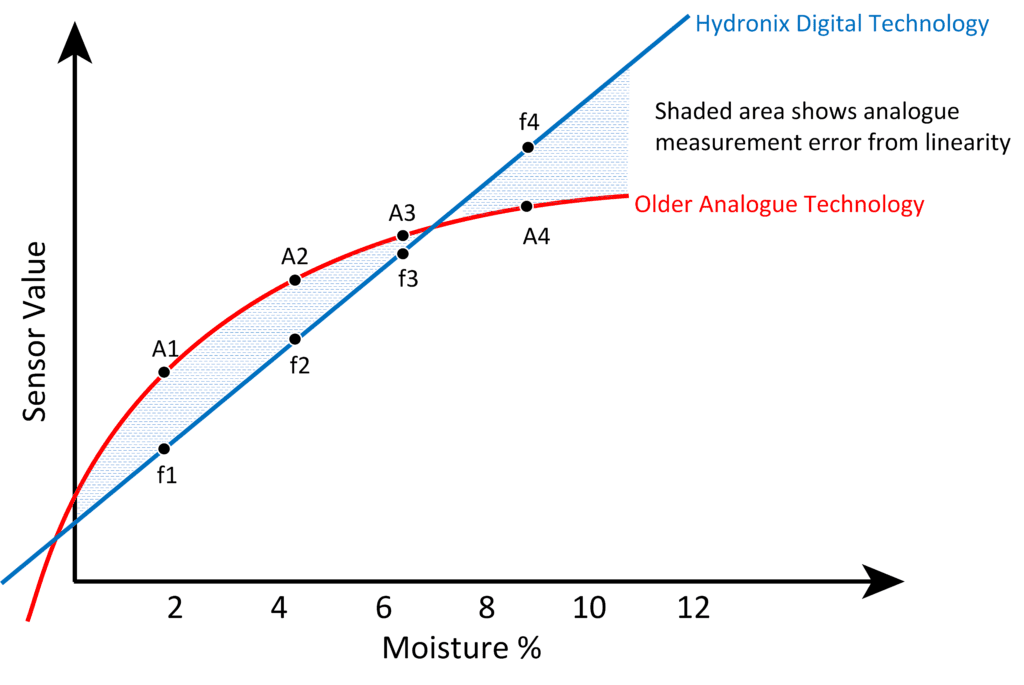

Older technology, as used in analogue microwave sensors, has a nonlinear measurement, meaning that the sensor reading, and the actual moisture content are not directly proportional. This makes these sensors very difficult to calibrate as they require numerous points to fit the curve. Their nonlinearity also implies that they offer low accuracy (Figure 1).

By contrast with these older techniques, Hydronix sensors use a digital multi-frequency measurement technique. The advantage here is that this provides a linear measurement, where the sensor value and water content are directly proportional to each other. The sensor is more accurate throughout the moisture range and can be calibrated more precisely. Because it removes the need for recalibrations after commissioning, this has lower lifetime costs and is the recommended method for all coffee producers.

Each Hydronix food production moisture sensor is made up of a single, intelligent unit that contains all the necessary on-board functionality, including signal processing and averaging. The sensors are also built from high-quality materials, contributing to extreme reliability and high durability.

By using our passion and expertise to provide the best possible digital microwave moisture sensor technology, Hydronix is helping build a more sustainable future for our children and the generations to come.

Hydronix has a complete network of local expert engineers in over 90 countries, speaking your language… meet them over a nice hot cup of coffee and see how they can help improve your process.