Control Slump in Concrete Production using Moisture Sensors

Concrete has a worldwide consumption of approximately 1 ton per person per year, making it the second most consumed substance on Earth after water. It is comprised of three elements, aggregate and sand (filler), cement (binder) and water. When combined in the correct ratios, these elements create a chemical reaction which enables the concrete to set.

There are two distinct types of concrete, Ready Mix and Precast. Ready Mix concrete is typically manufactured in a batching plant and delivered to site by truck mixers where it is used in its freshly mixed state. Precast concrete is used to make individual cast concrete elements which typically form part of a larger structure. This type of concrete is made inside a specialist plant and is subject to more rigorous quality standards, and the control of moisture is a vital part of the manufacturing process. Both types of concrete require manufacture to a specific recipe with the materials in the correct ratio levels to ensure consistency, quality and concrete strength.

The concrete producer will often use a slump test to check for workability, fluidity and consistency of the concrete mix. There are various factors that will affect the slump test including ratios of the aggregates, admixtures and also moisture content. This note will describe how the addition of digital microwave moisture measurement into the concrete plant can help to produce consistent concrete batch after batch and therefore also consistent slump properties.

Why is moisture control important?

In an ideal world, both the aggregates and cement would be completely dry so the amount of water required for each batch would be a set volume and the quality of the concrete produced would be identical batch after batch. However, aggregates are typically stored in a stockpile, usually outside, and although good storage can help, even for materials stored in covered bins the moisture held in the aggregates will be constantly changing due to the inevitable effects of drainage.

In modern concrete batching plants the amount of materials required for the recipe are typically weighed and the recipe is calculated using the assumed “dry” weight of the materials. However, within the weighed aggregates there will be an unknown amount of water. Although this note concentrates on slump, surplus water or moisture content in the sand and aggregates can also have dramatic effects on the water/cement ratio, the aggregate/cement ratio, yield and also the colour of the mix. This will lead to inconsistencies in slump, strength, colour and quality with an inferior product as the end result.

Why is the correct moisture calculation important?

If the concrete producer follows a set recipe using weighed amounts of aggregates and cement, then adds the amount of specified water to the mix, each batch produced will vary due to the unknown and differing amount of water held within the aggregates. For example, if a recipe specifies 1,000 kg of aggregates then unless these are 100% dry then the amount weighed will not be 1,000 kg of aggregates but a mix of aggregates and water.

Moisture calculation

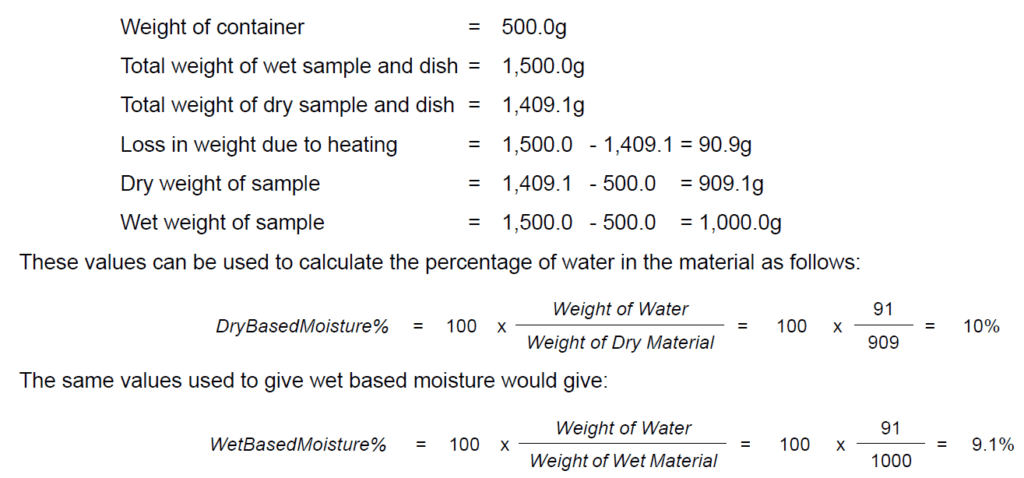

The only way to accurately determine the moisture of an aggregate by laboratory testing is to take a sample of the aggregate, weigh it (and its container) and dry the sample to evaporate the water, then to weigh the sample again. Normally a second and third drying cycle is performed as necessary until there is no additional loss in weight (meaning that the sample is completely dry). Calculations are then performed to correct for any additional moisture in the materials ensuring that the aggregate ratio is correct according to the dry weight mix recipe. An example of the calculation is shown below using simple numbers to explain the concept.

It can easily be seen how the measurement basis needs to be kept consistent through any moisture calculations and working.

The benefit of working with dry based moisture values is that it is much simpler to use these to calculate a target weight from the design weight.

How changes in moisture affect material ratios

The following examples demonstrate the effect of moisture variations in the aggregates to the ratio of materials in the mix. Other than total moisture, the ratio of materials in the mix is a key factor in determining the slump of the concrete.

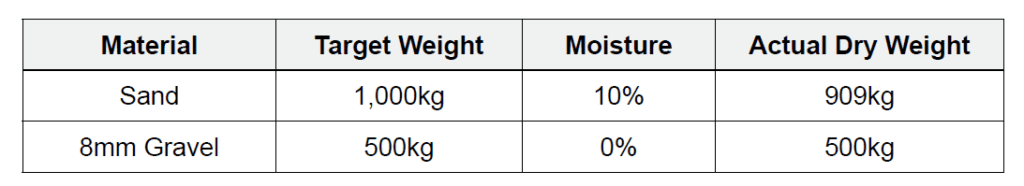

If a batch is weighed that has 10% moisture in the sand and 0% moisture in the gravel (by the dry weight method), then the following table shows the material mix:

The proportion of sand to gravel is 1.8 : 1

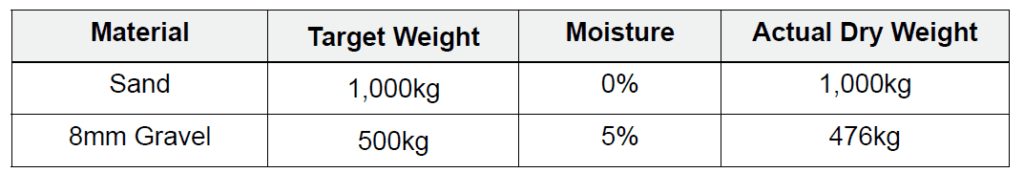

However if a second batch is dosed, this one with sand at 0% moisture and gravel at 5% moisture:

The proportion of the sand to gravel is now 2.1 : 1.

This produces a significant difference in the ratio of materials between the batches, and unless corrected, will directly impact on the quality of the concrete produced. It is therefore essential that the amount of water held within the aggregates is accurately measured and the dry weight of the material to be added to the mix consequently adjusted.

The final water added in the mixing stage may be adjusted based on the aggregate moisture contents to achieve an accurate water/cement ratio and consistent slump. However, for optimum performance, it is recommended to separately control moisture and water addition in the mixer.

Problems associated with variations in moisture

If the concrete mix is in the wrong proportions or the moisture level is incorrect this will create issues with consistency, workability or slump of the concrete. Ready Mix producers have to ensure that their concrete will still be at the correct consistency and be able to produce the correct slump and strength when delivered to the customer.

For Precast Concrete producers, variations in moisture will also cause problems with moulds and formwork when manufacturing components. Examples of this include pipes collapsing after the core is removed or blocks falling apart after exiting the block machine. Hollowcore concrete slabs are also noticeable examples where the concrete can sag or deform as the Hollowcore machine moves down the line. One of the other problems associated with moisture variation in aggregates, is that the surface area of the aggregates will change (i.e. less aggregates than expected). This is of great importance when adding colours to a batch of concrete, as coating of the surface area by the colour pigment will vary as the mix proportions change. This will cause colour inconsistency across different batches which may lead to the costly expense of additional colour to correct for this.

What moisture measurement method should I use?

Although the results from laboratory drying tests are accurate they are time consuming and this method does not allow for any changes to be made to material ratios in real time. There are several different methods of moisture measurement, such as capacitive, resistive, Infra-Red and microwave which can be used to automate the process and which have their own advantages and disadvantages. One of the most popular systems is microwave, however unlike other systems that measure using the analogue method, Hydronix sensors use a unique digital microwave technique which is not affected by impurities, colour, particle size or temperature, and is accurate to +/-0.2%.

Cost benefits using microwave moisture measurement

As well as an immediate improvement to the quality and consistency of the concrete produced, batch after batch, the concrete producer will also benefit from increased profitability. This can be defined either by a reduction in the amount of spoilt material or waste, or by an improvement in the efficiency of the material being used. Benefits include:

- Reduction in the amount of spoilt materials from inconsistent mix ratios

- Reduction in amount of cement used to reach correct strength

- Consistent repeatable quality

- Consistent workability and slump

- Consistent surface finish

- Colour additives may be used more efficiently

Which sensor?

Hydronix offers a choice of digital microwave moisture sensors that can be installed in different parts of the process. All Hydronix sensors measure at 25 times per second and relay moisture data to the control system in real-time, enabling immediate adjustment to be made either to the amount of aggregates being weighed, the mix of materials or to the amount of water added into the mixer. Hydronix sensors also do all of the processing directly within the sensor itself and send a true linear output to the control system unlike other sensors available on the market.

Measuring moisture in aggregate bins, hoppers and conveyor belts

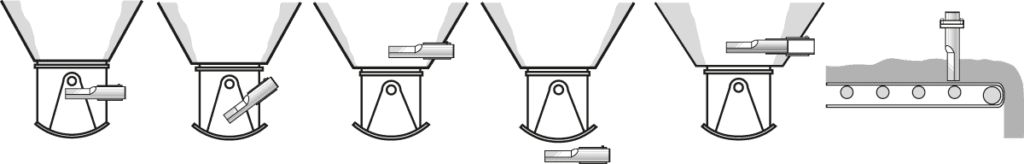

Moisture measurement using a Hydro-Probe sensor is usually carried out near the gate of the aggregate bin as this ensures the most reliable readings with the aggregates passing across the ceramic sensing head without impeding the material flow. Depending on specific plant requirements, the sensor can be installed in the neck or underneath the bin.

Once the sensor has been set up correctly, moisture readings can be taken as an average for each batch, and the plant’s control system can adjust the weighed weight of each aggregate in real-time. This will ensure the correct dry weight is batched.

Conclusion

The addition of digital microwave moisture measurement and control into the process provides a simple and cost-effective solution for the concrete producer. The resulting concrete will be consistent batch after batch, improving product quality and reducing wastage or spoilt materials. Moisture control can easily be installed into new or existing plants and the return on investment can be seen in a short time, very often just months after installation depending on the output of the plant.