Controlling moisture in the Rapeseed Oil extraction process

Rapeseed oil is extracted from the seeds of the plant commonly known as oilseed rape. Rapeseed is an increasingly widely cultivated plant that has become popular due to its beneficial health properties. Rapeseed oil is low in saturated fat, high in unsaturated fat and contains antioxidants. These characteristics make it a popular choice to fill the gaps created as global demands shifts to non-animal products and increased health awareness. A by-product of the oil extraction process is rapeseed meal, a protein-rich substance that can be used as an animal feed ingredient.

The need to measure the moisture content of rapeseed

The rapeseed oil extraction process benefits from moisture control for several reasons:

- Correct moisture levels for the oil extraction process

- Increased product control

- Reduction in waste and spoilt product

- Direct continuous, real-time, control of the drying process

- Monitor the material during the entire process, from delivery to the final product.

Control of the moisture during processing and for storage is vital to produce a final product suitable for its intended market.

The benefits of installing microwave moisture measurement sensors

- Dryers can be used more efficiently thereby reducing energy costs

- Improved and consistent product

- Reduction of spoilt/wasted material

- Not affected by dust or colour

- Real-time Automation of the drying process, reducing the need for manual intervention

- Reduced process downtime

Recommended installation

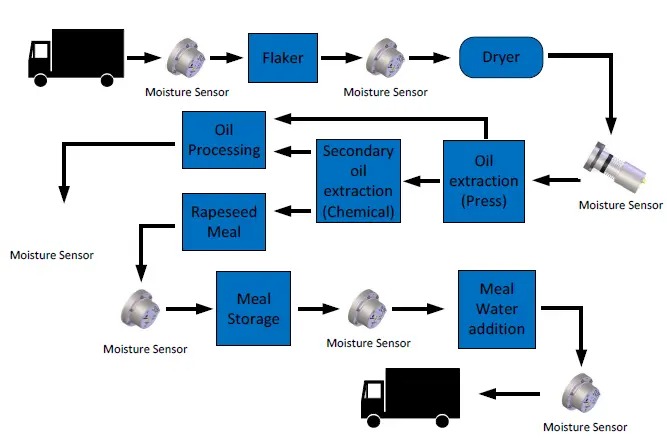

You can install a moisture sensor at various stages during the oil extraction process:

- Raw material delivery to site

- After Conditioning

- Before/After drying

- After oil extraction

- Rapeseed meal

In the following example, a sensor is installed after the seeds have been flaked and dried. The sensor is installed at the output of the dryer, enabling the control system to adjust the temperature to control the final moisture content.

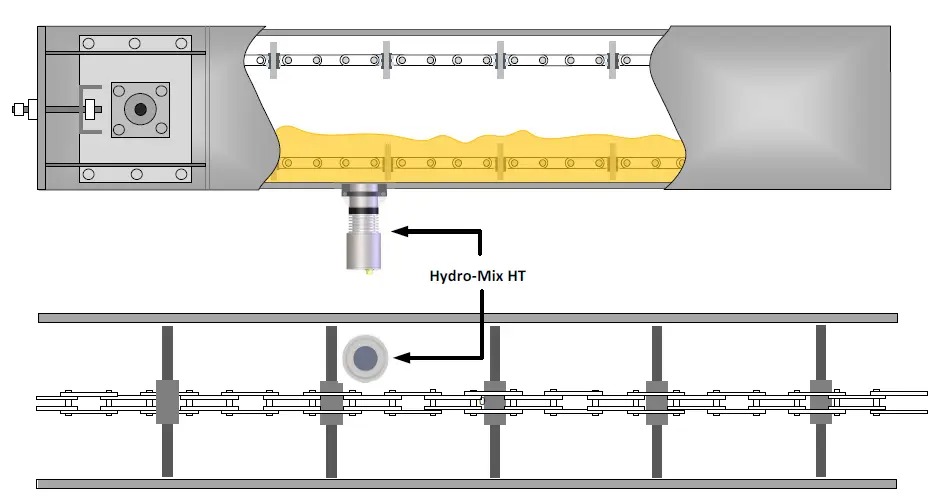

The sensor is installed on the underside of a chain conveyor. Due to high process temperatures, a Hydronix Hydro-Mix HT sensor is required. If a location with a temperature below 60°C can be found, a Hydronix Hydro-Mix XT sensor can be utilised instead. The sensor is installed so that the sensing face is flush with the internal wall of the conveyor, enabling the chain to push material over the sensor and clean the ceramic face.

Result after installing the sensors

A well-implemented installation will measure the moisture levels of the materials to an accuracy of +/- 0.5%, enabling the production process to be controlled more precisely. Real-time control of the dryer (as opposed to waiting for oven tests) ensures that the dryer is controlled instantaneously resulting in increased energy efficiency. There is also a reduction in the amount of substandard or wasted product caused by the time delay between periodic sampling and subsequent dryer adjustment.

Hydro-Mix HT sensors

Hydro-Mix HT sensors are constructed of stainless steel and have an abrasion-proof ceramic measuring faceplate. The sensor is designed to be installed flush-mounted with the surface of the mechanical material transport system allowing the material to flow freely over the measuring faceplate without causing any build-up.

Hydronix sensors have configurable parameters for built-in filters to reduce and eliminate noise caused by flow disruption. The sensor features numerous output options available directly from the sensor or via Hydronix gateway devices. The Hydronix Hydro-Com software enables simple set-up and configuration of the sensor using a PC or laptop and USB connection.

Conclusion

The inclusion of a microwave moisture measurement system into the existing process will help you to:

- achieve consistent quality products

- reduce the number of spoilt materials

- provide instant savings

- repay its capital expenditure in a very short time.