Sugar Beet Shred

After sugar beet pulp has been processed, the leftover material is used as a raw material for animal feed by-products.

Measuring the moisture during the production of the animal feed pellets, particularly during the drying process, is essential.

The material leaving the dryer must be at the correct moisture level so that it can be easily pelletised. If it is too wet, it can cause the machinery to jam or the pellets to go mouldy during storage. If the pellets are too dry, this will result in brittle pellets, which will crumble and be unusable.

Typical Applications

Typical Materials

- Sugar beet shred

Process Control

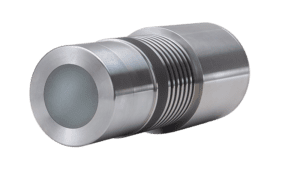

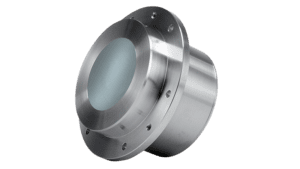

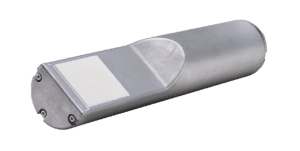

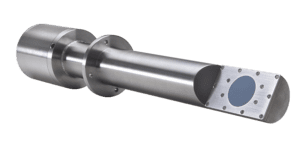

Related Products

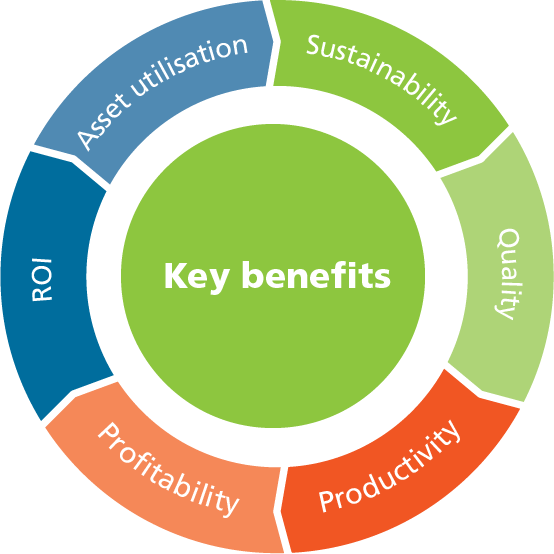

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Controlling Moisture in Dried Sugar Beet Pulp

The increasing cost of inputs such as raw materials, energy and labour are forcing sugar beet processors to look more closely at controlling their overall cost of production. A simple…

Read more