Powders

When manufacturing powders, it is common practice to concentrate a liquid before spray drying, and this is often done in an evaporator.

Measuring the precise level of concentration of the liquid enables repeatable control of batches leaving the evaporator. This provides increased and consistent product quality whilst reducing the amount of rework or wasted materials.

Typical Applications

Typical Materials

- Cacao

- Flour

- Other foodstuffs

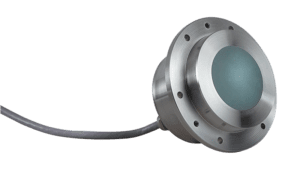

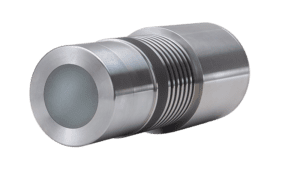

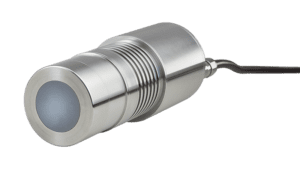

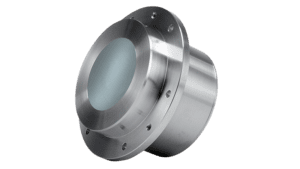

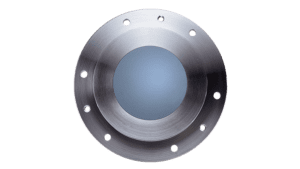

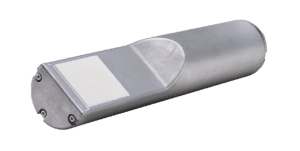

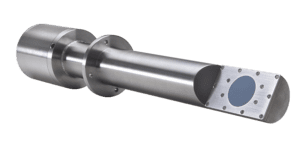

Related Products

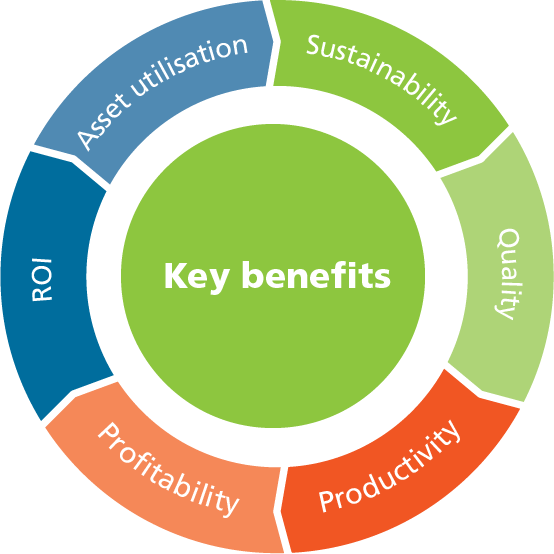

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

7 things to consider when improving moisture control in food production

In the manufacture of foodstuffs, achieving the right moisture content is paramount. Too little moisture in the ingredients and the product might go stale too quickly or have an incorrect…

Read more

Concentration Measurement in Cocoa Powder Production

When manufacturing powders, for example, dried drinking chocolate, it is common practice to concentrate a liquid before spray drying and this is typically done in an evaporator. The material is…

Read more