Precast Concrete

Precast concrete manufacturers need to produce consistent quality products and so need precise control of both the proportioning of the raw materials and the moisture level of the mixed concrete being produced.

Online moisture measurement allows optimisation of cement, admixture and colour use. This enables costs to be controlled.

Typical Applications

Typical Materials

- Concrete

- Aggregates

- Sand

- Stones

- Other aggregates

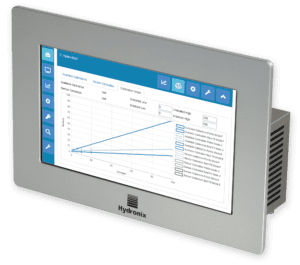

Process Control

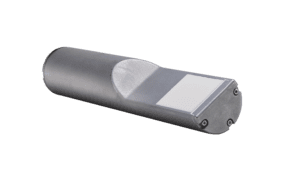

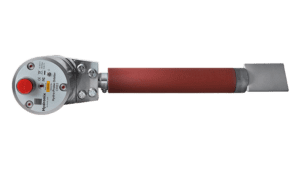

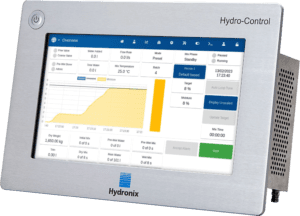

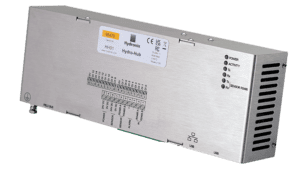

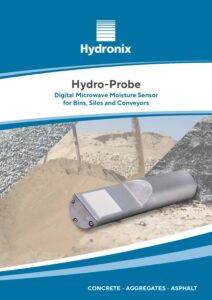

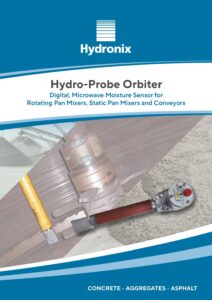

Related Products

Product Overview

CONTROLLING MOISTURE IN CONCRETE BATCHING

This video provides an overview of the Hydronix product range specifically designed for the concrete & construction industry.

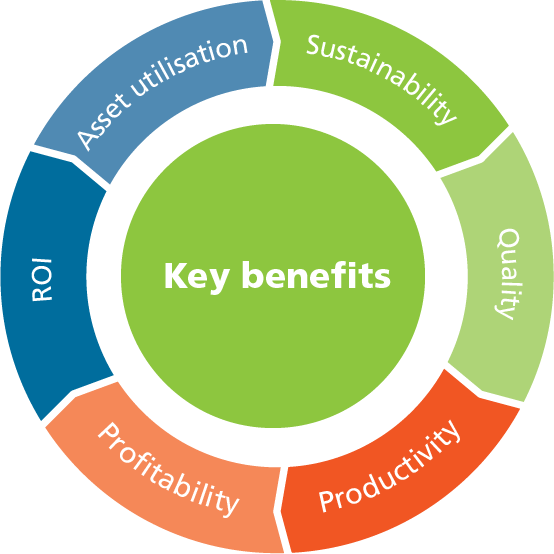

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Moisture Measurement – an Essential for Automating Concrete Production

The current worldwide health challenges are causing many organisations to adjust their working practices to minimise the staff involved in a site whilst still managing full production schedules. Automation is…

Read more

Capturing and using moisture measurement data: ‘Big Moisture’

For many industries, measurement and control of the moisture in materials is vital. Whether it be adding the incorrect amount of water spoils the product or over-drying it wastes energy,…

Read more