Aquafeed

The moisture can be monitored in various steps of the aquafeed production process, such as storage, grinding, drying, conditioning, and pelletising.

Measuring the moisture in fish meals enables the protein ratio of the final feed to be optimised.

Other benefits include improving profitability in the processes, while saving energy, and reducing waste and carbon footprint.

Typical Applications

Typical Materials

- Fish

- Shrimp

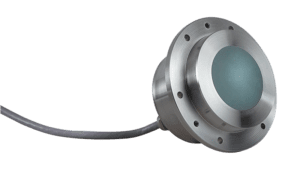

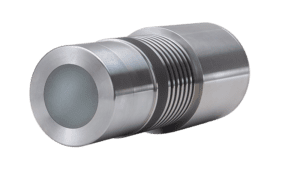

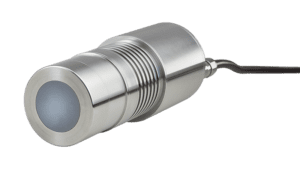

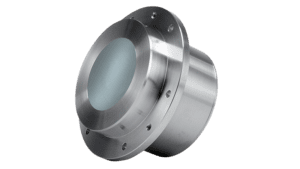

Related Products

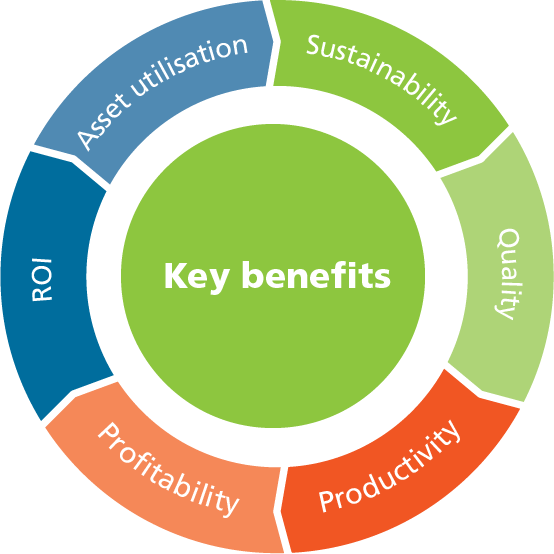

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Content

Water Underwater?

One of the significant factors in feed production is the ingredients’ moisture content. At various times, this needs to be raised or lowered to produce a particular consistency or otherwise…

Read more

Is water killing your fish?

Benefits of Moisture Measurement and Control in Aquafeed Production The key to optimising aquafeed production processes is to ensure stability and repeatability. Other than the quality of ingredients and process…

Read more