Agriculture – Grain Moisture Sensors

Whilst processing cereal crops, nuts, and pulses, moisture measurement can take place in several stages, such as raw material intake, conditioning, drying, milling/grinding, and packaging.

Measuring the moisture allows the producer to optimise milling and grinding performance, reduce the amount of energy required to dry the material and ultimately improve the shelf-life and consistency of the final product.

Typical Applications

Typical Materials

- Grains

- Nuts

- Cereal grains (wheat, corn, barley, oats, rice, …)

- Soyabean

- Pulses

- Agricultural material

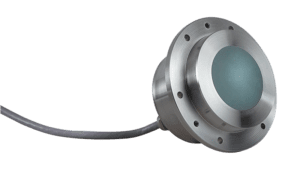

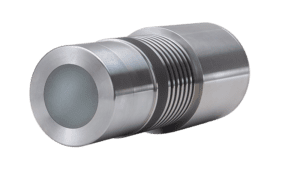

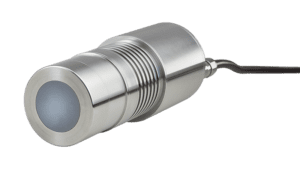

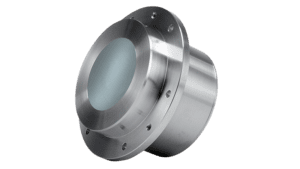

Related Products

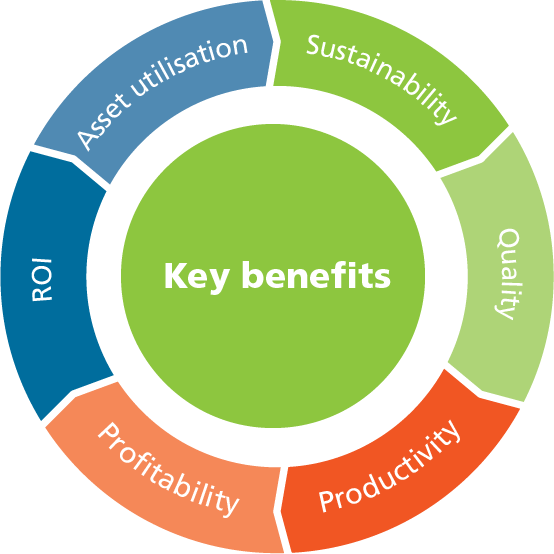

Key Benefits

Asset Utilisation

- Increase overall equipment effectiveness

- Reduce unplanned downtime

Sustainability

- Lower carbon footprint

- Save energy

Quality

- Less waste

- Consistent final products

Productivity

- Increase production yield through efficient use of material

- Online instant monitoring eliminates manual testing

Profitability

- Reduce waste and energy

- Automate processes

Return On Investment

- Average ROI in 3 months

- No need for expensive ongoing maintenance contracts

Related Videos

Why Should I Care about Moisture?

Edited 14 February 2024 Benefits of Measuring Moisture in Grain Processing Recent advances in moisture measurement technology are enabling forward-thinking businesses to achieve better control of their grain processing operations,…

Read more

Using Moisture Control to reduce the environmental impact of Agri-Food processing

Few people realise that around 30% of the world’s energy is consumed by agri-food systems [1]. Energy is also responsible for a third of agri-food systems’ greenhouse gas emissions. Given…

Read more