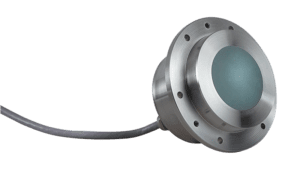

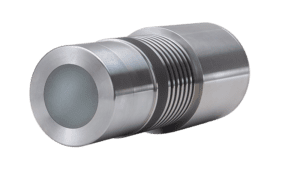

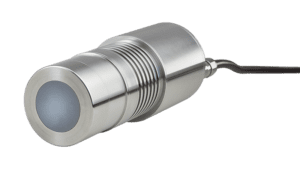

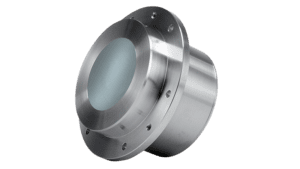

Pelletising / Extrusion

Overview

During the pelletising and extrusion processes, moisture is important as it directly affects the quality of the final product and can cause major problems with machinery when incorrect moisture levels are used. To optimise the process, it is vital to measure the flow of incoming material and correct the moisture during the conditioning process.

Benefits

- Reach optimum moisture target

- Reduce output variability

- Produce consistent and repeatable product